Producing fully-functional dentures from 3D printers is a novel idea. Wouldn’t it be fantastic if manufacturing dentures meant all you had to do was push the button on a 3D printer? Unfortunately, it’s not that simple a process. Still, the 3D printer is a high technology machine that offers great potential and many advancement opportunities for dental practices and dental laboratories.

Already, digital technologies are revolutionizing the way dentures are made. For example, CAD/CAM milling technology has been used for many years now to manufacture scaffolds for crowns, bridges and prostheses digitally. During this process, a dental technician first constructs the desired design on a screen and then uses the file generated from the design to control the milling machine. Typically, the framework is constructed by the milling machine from materials such as all-ceramic, or titanium before being manually completed.

This achievement enables the precise construction of well-fitting, aesthetically-pleasing and strong dental prostheses.

Clearly, CAD/CAM technology is highly advanced. Now more recent development is seen an introduction of practice 3D printers in laboratories. What then is the difference between CAD/CAM milling-technology and 3D print-technology? It all lies in the way objects under construction on the computer are built. 3D-Print = additiv, by applying material. CAD/CAM-Milling = subtraktiv, by ablating material.

Advantages of 3D printing

The biggest advantage of 3D printing is that objects of almost any geometrical form (including normally „tricky“ constructions) can be printed. Here, CAD /CAM milling machines reach their limits. Furthermore, 3D printing consumes fewer materials due to the additive process. 3D-Printer also do not have any components that could require replacement due to wear out.

3D printing does, therefore, bring a lot of potential that can expedite the digitalization of process chains in dentistry. However, technology alone is not enough.

The different Materials for 3D printing

The issue of 3D printing materials is a big challenge in the field of dentistry. Theoretically, and from a technical perspective, 3D printing of dentures is a sound idea. Practically, however, having the right materials is a significant barrier in the use of 3D printers for dental purposes. This is because dentures require highly sophisticated materials. Quality dentures have to get the „natural-teeth“ colour right; they have to be biocompatible and durable enough to withstand different influences in the mouth, such as extreme temperature changes and high chewing forces. They should not also release any harmful substances as they naturally wear out.

Even though 3D printers are not yet applicable to dentures, more and more laboratories are investing in their own practice 3D printers.

In addition, the materials used should be able to create a smooth surface so that no plaque can adhere. Most importantly, the material must meet the criteria set by the CE/FDA (approval certification for materials for medical devices in the EU and USA). Scientific research is trying to find a way around these many challenging material requirements, and a lot of developments are currently being made in this area. At the moment, most 3D printing resins available on the dental market do not allow for the production of definitly dentures.

An interesting development occurred in February 2020, when the dental company BEGO (Bremen, German) introduced an approved technology that allowed 3D printing of individual crowns, inlays, onlays, and veneers using ceramic-filled hybrid materials. It is the world’s first such technology now found under the name VarseoSmile. Further, initial scientific studies in this direction are promising, and even though 3D printers are not yet applicable to dentures, more and more laboratories are investing in their own practice 3D printers. These can be used primarily to manufacture auxiliary structures such as jaw models (e.g. aligner models), drilling templates (dental implants), test prostheses (try-ins) or impression trays.

3D Printing Process Chain

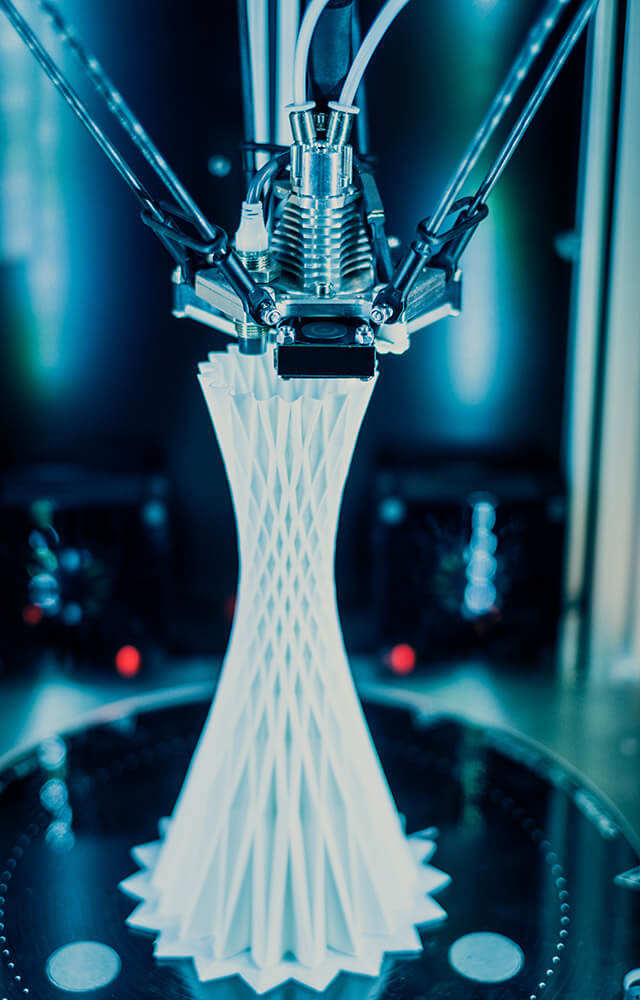

A brief look at the 3D printing process chain is as follows: A dental technician uses a virtual 3D model on the computer to construct a three-dimensional object. The STL file that is generated is then transferred and opened in a dedicated slicer. The slicer chops the STL file into wafer-thin slices and transmits this data to the 3D printer so it can create the object. The object is created layer by layer like a 3D puzzle by the printer. Usually, resins are used for printing; however, metals can also be used in industrial productions for printing, for example, in the laser sintering process.

The future of 3D printing in dental work

3D printing has become increasingly relevant in the field of dentistry. Further areas of application will follow as soon as materials research has developed appropriate materials. Here is what is on the ground so far:

- 3D printing is primarily for to manufacture auxiliary structures such as jaw models (e.g. aligner models), drilling templates (dental implants), test prostheses (try-ins) or impression trays.

- 3D printing is primarily for to manufacture auxiliary structures such as jaw models (e.g. aligner models), drilling templates (dental implants), test prostheses (try-ins) or impression trays.

- 3D printing is now possible of individual crowns, inlays, onlays using ceramic-filled hybrid materials, but more scientific, clinical research is needed

- 3D printing of ceramic objects (zirconia) that are polychromatic is promising.

- Specialists at LMU Munich (Ludwig Maximilians University Munich, Germany) have, for several years, tested multi-material 3D printing.

- Bone implants (e.g. for the jaw) made from special plastic and which are stable, and free of defects can now be precisely fitted after 3D printing.

- Researchers at the Fraunhoer Institute in collaboration with European partners are investigating a process where bone implants can be printed from a special plastic. During the printing process, the individual layers are coated with a cold plasma jet, a treatment that supports the growth of bone-forming cells on the surface.

Conclusion

3D printing is been successfully applied by laboratorys and industry companies in some areas of denture production. Basically, this innovative technology is very innovativ. Despite this, more digital advancements und research are required to produce dentures (medical devices) to a greater degree. 3D printing of dentures should incorporate functionality, aesthetics, dental phonetics, and materials science as well as craftsmanship and empathy. After all, the field of dentistry does not just process data; it creates new teeth for people.